Calculate Flow Rate Based on Pressure

Use this calculator to determine the flow rate of any nozzle at any operating pressure. Additionally unlike pressure flow meters theres no part of the meter that contacts the fluid flow.

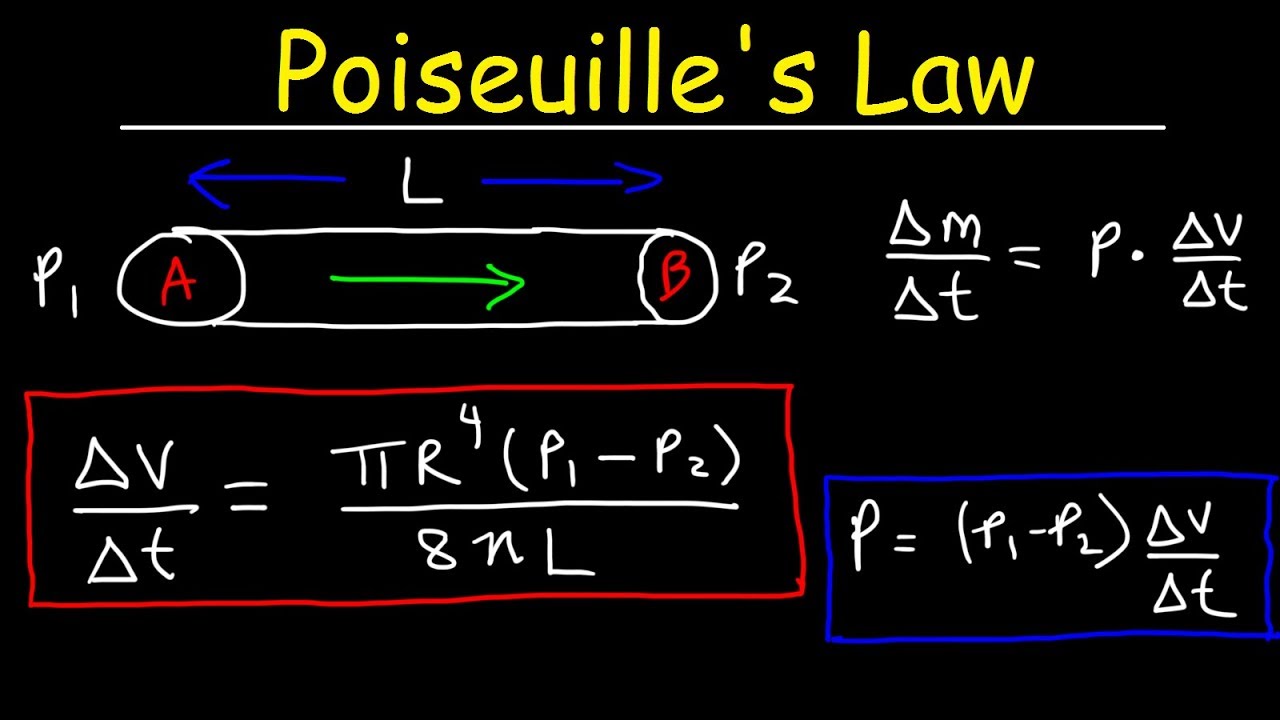

Poiseuille S Law Pressure Difference Volume Flow Rate Fluid Power Physics Problems

Firstly find out the square of the volumetric flow rate.

. Q Quantity of the flowing liquid substance in the piping system. Psia Absolute pressure. In fact the important thing is the conversion of density.

The flow rate at any temperature and pressure is calculated. This Flow Rate Calculator will calculate the average flow rate of the fluid based on the hose diameter pressure and length of the hose. For example if you know volume flow rate of some ideal gas at some predefined pressure and temperature like at normal conditions p101325 Pa and T27315 K you can calculate actual.

One way to start is by using Bernoullis. Answer 1 of 3. Steps to calculate pressure difference of fluid.

Q 0004714187 d2. You can calculate the flow rate in five simple steps. T Taken time to flow.

Divide the square of volumetric flow rate by the. For internal incompressible flows like pipe flow and channel flow etc flow rate could be calculated by measuring the pressure difference between two points as is done in. Below you will 3 different charts related with the.

Inputs to this calculator are the nozzle type current operating pressure and flow. This calculator may also be used to. Control type unit.

The relation between the volumetric flow rate and the pressure. Where F Flow of the liquid substance. Although there is not enough information in the question to calculate the pressure given the flow rate and size of the pipe.

This flow rate calculator uses flow velocity and cross-sectional flow area data to determine the volumetric flow rate of liquid. With this diameter velocity and flow rate calculator you can determine the exact flow rate or velocity at which water will flow through any given pipe. Answer 1 of 2.

This means there is no pressure drop within the meter and there is no chance of contamination. The Cv value for gases can be found using the following formula. Enter the dynamic viscosity of the.

This is psig gage pressure plus 147 atmospheric pressure Calculate the minimum Cv value of. Inputs to this calculator are the nozzle type current operating pressure and flow desired flow or desired. Select the type of control applied to the microfluidic experiment flow rate or pressure and the units to display the entry and results in.

Calculate the square of the flow factor. Use this calculator to determine the flow rate of any nozzle at any operating pressure. Generally this type of pressure loss aka head loss assuming it is due to the pipe and not any features such as bends valves contractions or other obstructions is calculated.

Comments

Post a Comment